BLACK CRYSTAL OIL & GAS

OUR RESOURCES

Four primary resources that are essential to our operations are, the people that work for us because they bring value to our operations; our strategic imperatives that serve as a guide for our current and future operations and it keeps our vision and mission goal in alignment; our Oil and Gas services which we depend upon for our growth and sustainability; and finally research and new technology which we depend on to grow our business and stay ahead of the pack in the industry.

The most significant resource we have is our people. We consider our employees to be the most valuable corporate resource/asset we have. They are worth more than gold” and we look forward to employing self-starting, visionary people, who exhibit the quality of dynamic leaders.

Black Crystal Oil and Gas is a diversity sensitive organization where people are allowed to respect, interact and be the best they can be individually and collectively, in pursuit of self-actualization and/or group identity.

DIVERSITY here in our company means

Different Individual is Valuing Ethnic, Racial, Social/physical differences with Impartiality, Truthfulness, and Youthful objectivity

Our people are the primary and most important resource we have. They constitute the core of our operations.

We consider them not only a significant part of our assets, but they are thought of as value creators, and thus are valued. Investing in human capital is one of our greatest assets and corporate strengths.

Why Work For Black Crystal Oil &Gas?

- We are a growing independent privately owned Oil & Gas Company with great potential for growth, with potential for becoming a major player in the global operations of oil and gas. We aspire to be recognized as one of the best, if not the best in the petroleum crude oil and natural gas, and petrochemical industry.

- We provide extensive and practical on-the-job training for our employees in diverse professions such as geology, geophysics and petroleum engineering.

- We provide paid vacations and holidays

- We are operated with basic family values and respect for diversity

- We use cutting edge state-of-the-art technology to assist you in your daily tasks

At Black Crystal Oil & Gas, we employ open minded self-starters and team players. We want our employees to be responsible, accountable go getters with proper understanding of the Company’s vision, mission, goals and values, who will also keep an eye on our bottom line. We encourage the recruitment of professionals with skills necessary to achieve our company’s operation and management goals.

We also encourage the recruitment of generation X, Y and Z, this is a challenge that we take very seriously. These generations are incredibly savvy in advanced computer technology and information systems which are the key to our success. To provide the most efficient solutions for both onshore and offshore oil and gas well completion and production, we engage highly qualified and experienced oil and gas personnel with technical expertise in oil and gas well-drilling, completion and production. We hire professional surveyors, geologists, geophysicists, petroleum engineers, draftsmen, I- T. technicians, and oil-field site managers, to perform those functions within the organization.

Professional Petroleum Geologists Examine variations in rock formations and mineral samples to identify new gas and oil deposits; analyzes the integrity of wells to determine feasibility of drilling study and interpret well logs data obtained through electrical or radioactive well logging, analyze samples of cores and cuttings from drillings; and interpret other subsurface geologic maps or surveys to identify earth strata. They calculate and estimate drilling and completion depth, quality and vastness of deposits, work with site engineers to coordinate and bring the well in.

Professional Petroleum Engineers Design and supervise the process of drilling and production of oil and natural gas out of the ground and into the storage tanks; implement drilling and completion protocols; determine appropriate drilling approaches; choose equipment and supervise workers who install and operate drilling equipment; and process specialized extraction equipment; test samples of the oil-bearing rock layers; conduct reservoir tests; and simulate hydrocarbon extraction methods.

Professional Geophysicists Responsible for the use and integration of diverse new geophysical and geologic data applications, processing seismic data to generate high quality 2D and 3D seismic interpretations, maps and/or techniques covering a range of geological and geophysical rock formation environments.

Professional Licensed Surveyors Coordinate and manage field work and crews that collect information about the size and characteristics of the land; research legal records and documents to determine the exact boundaries and value of property; determine suitability of construction on the land. Measure site elevations (heights), contours (curves), points, and lines on the land's surface; use a variety of instruments and electronics, including the Global Positioning System (GPS). To ascertain accuracy of information collected, prepare charts, maps, and reports for use in well siting. Based on the surveyors' findings, geologists, engineers, and drafters decide on the most appropriate and economical location for the well and if modification should be made to the landscape including leveling of the site.

Draftsmen Calculate control sections and coordinate obtained raw data transformations with survey crews; identify potential pipelines boundaries and locations; display better understanding of the scope, requirements and methods of production operations, utilizing both manual drawing skills as well as computer-based technology data-base applications; using automated computer-assisted drafting; create both two-dimensional and three-dimensional renderings of the finished project.

IT Technician/Managers Implement new geophysical and geological related computer assisted software and hardware; update and manage work stations and servers; comply with data assistance requests from exploration and production staff; streamline operation of the IT section in alignment with the business objectives of the organization; plan, coordinate, direct, and design IT-oil and gas related activities needed for exploration drilling and production; provide administrative direction and support for daily operational activities of the IT section; work closely with management team and field personnel, to identify, recommend, develop, implement, and support cost-effective technology solutions for all aspects of our operations; define and implement IT policies, procedures, and best practices.

Oil Field Site Managers Set up and monitor project budget; review project proposal or plan to determine time frame, funding limitations, and procedures for accomplishing project objectives; implement staffing requirements, and allotment of available resources to various phases of project; assist in the preparation of design ideas and specifications; coordinate the activities of geologists, geophysicists,, engineers and I.T to design and develop preliminary plans, sketches, calculations, drawings in the development and preparation of exploration program; maintain constant communication with all the players involved in the conception through design, testing and production of oil and gas prospects; review and approve all detail designs, calculations, drawings, specifications; and prepare quality production plans and reports.

A site Manager establishes a work plan and staffing for each phase of the project, and arranges for recruitment or assignment of project personnel, confers with project staff to outline the work plan and to assign duties, responsibilities, and scope of authority; directs and coordinates activities of project personnel to ensure the project progresses on schedule and within prescribed budget; reviews status reports prepared by project personnel and modifies schedules or plans as required, confers with project personnel to provide technical advice and to resolve problems, validates and verifies all hardware; works closely with all other managers; prepares progress reports for management, clients, investors or others.

We look for uniquely qualified, competent, and skillful professionals as employees. They must be team players, dependable, responsible and eager to request and be given responsibility, while being held accountable for their actions, products and/or results.

- We want to hire employees with the ability, skills, knowledge and education that projects competency, self assurance, dedication, confidence, creativity and ingenuity, willingness to work, with resolve and drive to succeed.

- We want team players, motivated self-starters, open- minded, creative and innovative leaders with both the ability to lead and the willingness to be led.

- Our employees must be willing to work individually and in a team setting while respecting self and others, and treating investors, colleagues, customers, clients or fellow employees with dignity, professional respect, courtesy and uncompromising mutual understanding.

- We are willing to hire employees who believe in our corporate values and vision of excellence and respect for diversity; We seek employees with team spirit, who exhibit creativity and unity of purpose; who believe in the mutual benefit of idea-sharing, support holistic and non-monopoly of knowledge, and support the process of continuous learning as one of the best approaches to a better world, including the relentless use of “best-management- practices”

- We want employees, who are above average in performance; who believe in a servant leadership style of management; who like personal and professional challenges; and who see the company’s assets as valuable resources that should be improved and protected. We seek employees who are in charge of their own career development and hold the view that “the sky-is-the limit” in regard to performance excellence.

- We want to hire self-driven, flexible, utility-and-customer focused proactive planners and mangers with innovative and creative responses to achieving set goals in pursuit of the company’s overall strategic objectives.

- We want to employ open minds, creative, innovative and technologically savvy and morally competent employees who see adversities as opportunities; who are willing to meet future challenges with brilliant exuberance, while bringing new ideas and creative ways of thinking to the company.

Our administrative staff is comprised of a President, Owner and Chief Executive Officer in Dr. Jimmy Etti-Williams who has more than 30 years of technical and administrative experience as a Petroleum Geologist. Our other valuable employees are listed with their respective experience and background in our company directory.

It’s time to build your career in the oil and gas industry with us as a growing company. Come and be a part of the fastest growing minority-owned, private, independent oil and gas Company in the U.S.

A key resource essential to our overall development is the pursuit and completion of our corporate strategic imperatives. In support of our corporate strategic plans and in line with our organization’s vision and mission, the three strategic imperatives are to develop our upstream assets, expand the midstream infrastructures and increase all our downstream activities locally and internationally. These provide the operating framework and professional discipline we need to transform Black Crystal Oil & Gas into one of the leading independent private oil and gas producers in the world.

Upstream Strategy: We will continue to explore, drill, recover and produce underground (onshore) and/or underwater (off-shore) crude oil and natural gas fields and any known potential reservoir. We will encourage internal and external prospects including partnering with, or directly engaging a third-party producer, our own partners and other reputable major producers to drill exploratory wells for or with us; and subsequently operate the wells to recover potential petroleum crude oil and/or natural gas globally. Our upstream strategies will continue to be guided by our commitment and drive to invest in projects that deliver superior returns,; our ability to maximize profitability of existing and future oil and gas production; our resolve to relentlessly identify and pursue confirmed or potentially attractive exploration opportunities and, the willingness to take minimal risk and capitalize on the growing oil and natural gas markets worldwide.

Land Base Drilling Rig in Operation

Midstream Strategy: Our midstream strategy involves a long-term plan to own, operate, and manage refineries that will process our production stock. We plan to be involved in the midstream industry by processing, storing, marketing and transporting petroleum crude and petrochemical products from refined crude oil, natural gas, Natural Gas Liquids (NGLs), Liquefied Natural Gas (LNGs) –especially ethane, propane and butane, as well as other petrochemical products such as diesel, jet fuel, heating oil, asphalt, lubricants, synthetic rubber, plastics, fertilizers, antifreeze, pesticides, and pharmaceuticals.

From Production to the refinery

Downstream Strategy: We plan not only to own, operate and manage oil refineries and petrochemical plants that will refine and process crude oil and engage in sales and distribution of natural gas and products derived from processed crude oil; we will also handle processing and distribution of these petrochemical products including liquefied petroleum gas (LPG), and natural gas, to companies in our region of operations. Our long-range strategic goal is to establish our own private labeled gas stations nationwide under the “Black Crystal Oil” name, featuring our company logo, to distribute and sell our refined gasoline and other petrochemical products directly to the people.

Propane and Gas stations

We will process and distribute directly to other retail outfits refined petroleum products including, but not limited to, gasoline or petrol, jet fuel, diesel oil, heating oil, natural gas, propane, other fuel oils, lubricants, asphalt, petroleum coke, fertilizers, antifreeze, pesticides, synthetic rubber, and plastics, including pharmaceuticals. We will become highly competitive and take leadership role among independent producers in the oil and gas industry and wheel strong economic influence in the petroleum and petrochemical industries.

Our Services Oil and Gas exploration, drilling and production are our primary resources and will continue to be the major sources of our income. Oil and Gas production is a very complex process involving months and sometimes years of preparation and planning. While this process is a progression, that is expected to take few months to about 15 years or more (depending on variable factors), the actual drilling operations takes less than two months and involves approximately 15 to 40 different operations services, adhering to strict safety and environmental standards and practices.

The following outline key components of basic oil and gas production process

- Our Company Representatives

- Well Design team

- Geologist to sit on the well

- Petroleum Engineer

- Welding and Construction

- Roadway and Pit Site Construction

- Sandblasting and Painting

- Communication

- Fuel Supply

- Water Supply

- Electrical Supply (Temporary Electric Meter)

- Drilling Company

- Drilling Crew and team

- Rigging up

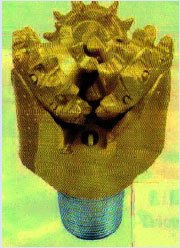

- Drill Bits and Selection

- Well Logging

- Well Control

- Pumping Services

- Cementing

- Mud Services

- Rental Tools

- Down hole tools

- Wire line operations

- Casing Operations

- Perforations

- Stimulation/ Fracking Services

- Waste Disposal

- Directional Services

- Transportation Services

- Well Servicing

To properly understand how oil and/or gas well is drilled, it is very helpful to observe and be part of the drilling process which include

- Preparation of the drilling site or well location (Roadway, site clearing pad site and rigging up process etc)

- Developing and installing utility infrastructures (Electricity, Water, Earthen or mud pit lined with plastic to prevent contamination etc.)

- Pilot Hole

- Mouse Hole (Storage of pieces of equipments like pipes at the job site)

- Rat hole (For racking the drilling pipes)

- Rigging up (it takes 31/2 days and 10 workers with 30 to 50 semi-trucks moving drilling rig assembly parts)

- Rig Inspection for specs and safety standards

- Setting up Drilling Stage 1 to set the surface casing 50 to 250 feet below the water table

- Drilling Stage 2 to Total Depth (TD)

- Tripping Out and Mudding up

- Blow Out Prevention (BOP) device on top of casing

- Designated Hole

- Well Logging at a depth of interest while hole is conditioned for logging

- Testing for completion using steel casing with smaller diameter

- Fracking the well

- Treating and Producing the well

- Shutting the well in if it fails

- Plugging and Abandonment

We take pride in our business, the people and processes involved in our operations; hence we would like for you to understand and learn more about our operations –especially what it takes to finance, find, produce, and distribute petroleum crude oil and natural gas from the ground in the field, to the market place.

A Drill Bit

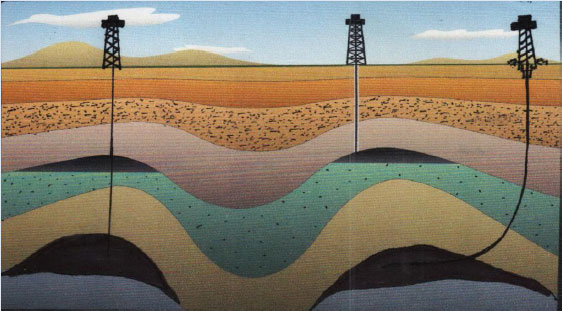

Drilling for Oil and Gas

From The Underground to the Surface and eventually to the Market, Black Crystal Oil and Gas is involved in the prospecting, exploration, drilling, production and marketing of Oil and Gas. Oil and gas exploration and production is a labor of love and it takes hard work, science, technology, dedication and involves risks.

We are involved in the entire process of petroleum crude oil and petrochemical exploration and production processes, from prospect generation, site preparation, general safety plan design, drilling, logging, fracking, well perforation, completion, production, well servicing, abandonment and plugging.

A full understanding of basic and advance geological/geophysical exploration and petroleum engineering concepts, challenges, expenses, environmental impacts, and financial risks involved in drilling for oil and gas wells is critical to successful oil and gas production, operation and management.

Vertical drilling was the predominant way of extracting oil and gas before. However, exploration for oil and gas has been stimulated in recent years by the development of horizontal drilling. A quick review of the huge investments and technical process and time involved in producing oil and natural gas is briefly explained below.

Black Crystal Oil and Gas is involved in the exploration, drilling and production of Oil and Gas from under the ground up to the surface and into your cars, homes and industries. B.C. O&G employed experienced and well-trained personnel to supervise exploration, drilling and production operations.

Our field personnel have many years of experience in oil and gas research and the design of down-hole tools. We engage veteran oil and gas service companies that specialize in drilling, completion and production operations, reservoir engineering, and reserve calculations workover, and pulse telemetry and electromagnetic communication technologies, gamma steering, dynamic pressure, positive displacement motors and well site data management including , seismic equipment services on either contract, charter hire, turnkey or integrated service basis.

We have in our services employees and consultants working in various capacities as petroleum geologists, geophysicist, and Land man petroleum engineers, and I T specialists around the country who know more about the oil and gas industry and the business of developing oil and gas wells and reserve fields. We also have prospectors from all over the world who finds and bring us new, current, abandoned, potential oil and natural gas prospects.

Geological exploration is one of the critical first steps, and probably the most important aspects of any oil and gas operations. Once the prospect is identified, the field is defined and the potential reserve confirmed, it is imperative that the producer quickly find funding for the exploitation program plan. Basically, the following are the process involved in drilling for petroleum crude oil and natural gas:

Our petroleum geologists and other consultants review submitted prospects to determine their merits and if they warrant further considerations and reviews or not. If approved for further review, our in-house Senior Petroleum Geologist will review the prospects first and a third-part independent consulting geologist with 20 years or more experience will provide a final review that determines the way forward.

Part of the review will involve the production history (date, daily, monthly and annual production data), number of dry holes if any; production statistics, producing formations and depth, pay zones, reservoir analysis seismic geophysical data, well logs, with 3D maps etc (all these information are provided by the prospector and reviewed by a professional geophysicist whose independent review is passed along to our division office for our team of analysts including our Senior Petroleum Geologist and the consultant to review and provide comment and feedback to our Operation Manager)

Once a promising an economically viable prospect is confirmed, our Land man is instructed to proceed on providing needed verification information on the acreage with onsite review showing any topographical anomaly and accessibility restrictions (swamp, wet land, hills etc) including any potential environmental concerns. The Land man will also conduct a lien review of the property or what is called a stand-up. A lease or purchase of the property is finally recommended with a “draft” potential plan for drilling submitted to the main office.

The prospector is contacted and notified of our interest and he or she is required to sign a confidentiality agreement document and a waiver indicating that the prospector waived all the rights to the prospect once we have acquired it and it cannot be shown or market through another third-party. As soon as legal documents are signed by all parties involved, we proceed to funding and planning for the drilling and producing the prospect.

Drilling Rigs & Operations

There are different types of drilling rigs, operating onshore andor offshore depending on location, the type of well, depth, well design and type of production. There is the land rig which can be permanent land based rig, skid-mounted, truck mounted andor a workover drilling rig. Workover rig is usually smaller in size and as indicated it is used for well servicing.

Onshore drilling rigs are either skid-mounted drilling rig, or a truck mounted drilling rig with a workover rig as option. Regardless of the type of drilling rig used onshore, any one of these rigs comes to the well site with, drilling and well completion components such as mud pump, draw works, hook, swivel, rotary table, camps, crown block, mast, substructure, and BOP.

Once a well has been drilled to its total depth, the drilling rig is moved off the hole of the well, and a service rig which is a smaller rig purposely-built for completions is moved on to the well to get the well on line.

A Land Base (Drilling Rig in Operation)

A thorough understanding of both directional, horizontal and/or multilateral drilling; including efficient coordination of production and tasks activities of field supervisors, tool pushers, site mangers, geologists, engineers and technical support personnel require strategic planning and implementation.

Drilling one or multi-dimensional directional andor horizontal well, with the best well design and multi-lateral completion methods using either rotary BHA’s jetting, whip stocks, motor, steerable motors, and/or rotary steerable systems can achieve better success with good drilling crew, best-in-class drilling technology and computer assisted well monitoring devices.

A successful drilling operation requires both professional geological and engineering knowledge and broad understanding of current drilling trends, new drilling technology, drilling operations guidelines, extensive well design planning, technical drilling and calculations--including interpretation of dogleg and its severity, TVD, polar, and rectangular coordinates and vertical sections. Also required, is broad base knowledge of well control procedures, mud logging data collection and interpretation, borehole cleaning, controlling drilling fluids polymers, drilling solids, and pore pressure integrity and determination, hydraulic optimization cementing requirements, blow-out prevention and well logging analysis and perforation experience.

Offshore oil and gas fields are drilled using Ocean or Marine rigs with extensive drilling platforms on a ship or a float. These rigs tend to have permanent massive structures and housing equipments used for operation and accommodation including catering services for the drilling and production crews. It could be two times the size of a football field with more than 150 drilling crew members, production engineers and other various personnel on board. It normally serves as a one-stop-well-service rig with complex geophysical and seismological equipment and tools; It has also completion, logging, perforation, fracking and cementing tools; workover rig, video with gyroscopic down hole tools, production and testing tools; plugging and/or abandonment equipment services.

Offshore Drilling Platform

The progression of our oil and gas operations normally starts with scouting, prospect generation and evaluation; followed by leasing and permitting for exploration. This progression is followed by site preparation, drilling, well completion, development and marketing. We begin our well bore operations with project planning, well design and site construction.

Drilling for Oil and Gas onshore

Field works include but may not be limited to spudding of the well, conducting on-site-safety review, safe drilling operations, logging to identify pay zones which are perforated base on recommendations. This is followed by fracking and full blown well completion, including development, production and well management.

Drilling for Oil and Gas offshore

Finally, we can send the product to the market following re-vegetation of the well surroundings putting it better than we found it. Our primary concern is for protection of the environment, adherence to government and industry regulations, and our commitment to a vision of reducing carbon footprint in all our developments and operations.

Research and Technology

Research and technology is another important resource essential to our exploration, drilling and production operations. This constitutes our principal resource and it serves as the foundation for our overall corporate strategic plan. With advances in technology in recent years, more energy efficient and environmentally friendly andor responsible technological materials, processes, methods and operating systems are available for coping with world Oil and Gas energy exploration needs.

Over the last decades especially, advance in drilling, completion and production technology has improved the petroleum crude oil and gas exploration to the extent that everything from well spacing to crude production and transportation are monitored by advance computer technology. With current technology, directional and horizontal drilling allow drillers to directly access previously untapped oil and gas reserves at depth and in formations previously considered unattainable or inaccessible.

Advanced Drilling Technology (ADT) such as multilateral, horizontal and directional drilling can be used in lieu of conventional drilling to avoid sensitive surface and subsurface environmental areas. These methods allow producers to produce oil and gas beneath ecologically sensitive surface and subsurface such as wildlife and conservation habitats, wetlands, beaches, recreational lakes, commercial and residential properties or areas. ADT facilitates multilateral drilling and completion through a single well bore while producing at different dept andor from multiple pay zones or formations. Horizontal drilling especially also allows more contact with oil and gas reserves that were previously considered unattainable thereby facilitates more production from the hidden reserves.

From black to gold: The Black “Crystal” Gold

Black Crystal Oil and Gas is committed to the use of energy research and technologies, which are dedicated to provide viable Oil and Gas from fossil fuel to sustain economic developments. Our goal is to enhance profitability, develop innovative technological state-of-the-art solutions that enhance and encourage the use of natural gas as a clean and cheapest source of energy.

New Drilling Technology as Resource

Until recently many oil and gas discoveries were considered uneconomic to produce for commercial purposes due to poor andor inadequate perhaps unavailable technology. New drilling technology with adaptations of drilling equipment and techniques such as multi-lateral horizontal wells, designer wells and precision-drilling developed in the mid- to-late 1990s were now making it possible to drill more wells by penetrating more of the previously difficult oil formations, and achieving unprecedented and exceptional production at substantially less cost.

New Drilling & Fracturing Technology

With new technology, oil and gas exploration has reached a new dawn in terms of science of oil and gas explorations, discoveries, drilling, well fracking, completion, production and management. The followings are some of the advances made in the oil and gas industry to-date.

1. Hydraulic Fracturing (HF)

Hydro-fracking is the traditional method of fracking which has been in used in the petroleum industry for well completion worldwide for a very long period of time. It uses water, sand, and various chemicals under intensive high pressure to break up perforate rock formations (with the sands acting as a wedge to open the fissures and allow the oil and gas within to be extracted). Primarily used for well completion and stimulation, hydraulic fracturing is also use for enhancing production rates in new wells. It has become standard practice in the industry to use hydraulic fracturing (HF) in secondary recovery for oil and natural gas wells stimulation. However, it has been used extensively in other applications involving coal beds, oil or tar sands and shale gas trapped in rock formations.

With the use of HF, vast quantities of oil and natural gas existing in previously abandoned and supposedly unrecoverable deep shale formations can now be extracted using hydraulic fracturing independently or in combination with highly sophisticated state-of-the-art new extraordinary drilling technique such as horizontal drilling, other fracking and completion methods and techniques.

Hydraulic fracturing or fracking as it is normally called, is a proven well completion technique used successfully worldwide by oil and natural gas producers to safely recover previously unrecoverable oil and natural gas from deep shale formations. Despite all the recent upsurge complaints and public concern about hydraulic fracturing, it is a safe and very efficient completion technique if properly conducted using modern sophisticated, and highly engineered and controlled procedure.

2. Petro-Frack Technology

This technique is new to the oil and gas industry but is making a lot of waves with success stories from Canada to places as far away as Netherlands. Petro-Frack literally uses petroleum as fracking liquid instead of water to release and produce crude oil and gas. It is a new state of the art fracturing technology. According to some oil experts, this is a green technology, very is eco-friendly, and more efficient than the conventional chemical-based hydro fracturing or hydraulic fracturing.

3. Cavitations Hydrovibrator

This is a relatively new, alternative “GREEN” technology compared to traditional chemical-based hydraulic fracturing, or “fracking,” used during completion following drilling in shale formation for oil andor gas. Cavitations hydrovibrator operates using pure water. It avoids using any of the 200 or more chemicals which are traditionally listed and used in the fracking process. These chemicals have been identified as sources of controversy, with allegation of contributing to environmental damages and/or contamination of local water tables thus creating serious problems for the oil and gas industry.

Cavitations hydrovibrator is mounted directly on a drilling line which can be inserted into either a vertical or horizontal borehole. Pressured water is fed into the cavitations hydrovibrator inlet through the drilling line using the drilling pump, while the water flow straight into the boreholes where the targeted gas-saturated perforated formation zone or stratum is located. The targeted oil filled formation zone is fracked with intense repetitious pulsating hydro-pressure from the hydrovibrator. Invariably, the pulsating hydro-pressure increases the degree of fracturing in the zone and results into further lateral expansion of the fissures liberating the gas within.

4. Horizontal Drilling

This a scientific and revolutionary new technical approach towards increasing oil and gas output, using creative innovative modern horizontal drilling method. It allows producers of oil and gas to efficiently and effectively run several long sections of horizontal tubing instead of vertical through a thin layer of rock formation or potential production zone with 6 feet perforated intervals of draining section along the said horizontal pipes. This method increases the amount of oil bearing formation section that can be drain effectively and efficiently through the well bore. This horizontal technique is gaining worldwide acceptance as the best drilling method to increase production especially in oil bearing shale’s or tight sand formations.

5. Three and Four Dimensional (3-D & 4-D) Seismic Imaging and Modeling

One of the most amazing and new scientific innovations in the oil and gas energy industry that have come about in the last decade is innovative advances that are taking place almost daily within the technology of “Three and Four Dimensional Seismic Imaging (3-D&4-D). Seismic imaging technology provide a true image of the subsurface geology of rock formations by inducing acoustic waves from near the surface of the earth penetrating deep into the earth generating and recording the reflective patterns of echoes produced from various stratigraphic formation boundaries in a three or four D colorful pictorial image. It generates clear pictorial images of the subsurface including any geologic changes in the rock formations or between wells. This seismic data can later be interpreted to help determine the extent and accuracy of any oil and gas reserves, and appropriate future well locations. This capability was not available years ago until recently. With three and four dimensional seismic color imaging, very accurate and clear images are provided that provide full picture of the “sub terrain formation in living color that greatly enhance geologist’s and geophysicist’s ability to review, identify, discover, extract and make drilling and/or production recommendations.

It is the most cost effective and efficient alternative to drilling supplementary reference wells to verify and confirm bed rock formation or lithology differences and similarity. With 3-D and 4-D seismic imaging, better evaluation of mineral rights and extent of potential land to be acquired can be made. It improves the success rates for oil and gas exploration projects, and provides a more complete evaluation of mineral rights and better understanding of the nature of prospects. Importantly, it enables and optimizes decision making for the best and exact wells locations thus preventing drilling of fewer dry holes. It could serves as a guide for horizontal and multi-lateral drilling program or schedule.

This state-of-the-art technology as a tool allows geologist or geophysicist to easily find expansive or restrictive oil reserve pools, with pin-point accuracy without guessing or estimating. 3-D and 4-D seismic technologies enable the development of reservoir models which accommodates complex geological interpretations, and ensures robust and reliable information for developing these models, improved decision-making, support more justifiable investments, and improved well completions and field performance.

Today, three and four-dimensional seismic imaging system technology is one of the most significant technologies in the oil and gas energy industry in the last 50 years. It is extending exploration reach, and optimizing production or recovery capacities in oil and gas deposits by reducing drilling risk and cost of explorations. It provides better understanding of the subsurface formations, through enhancement of seismic data with precise pictures of the form and shapes of the subsurface. This helps operators to literarily identify and select the best drilling location necessary to facilitate and maximize production. It has provided better opportunity for enhance oil and gas recovery --especially the efficient and expeditious recovery of heavy-oil in deep seated formations and/or reservoirs.

6. Through-Tube Rotary Drilling (TTRD) method

Through-tube rotary drilling method is designed to allow a new well to be drilled through existing production tubing of an older or new well as the case may be. Te existing or old well tubing doesn't have to be pulled out of the bore hole by the drilling rig before setting up to drill a new well at the same location hole. The technique tends to save tremendous amount of down-hole time and drilling costs. Normally, drilling crews and associated field personnel have to pull drilling pipes and replace tubing in a typical well and its time consuming and very costly. It is estimated that a potential saving of almost $1,000,000 per well can be expected using TTRD method (depending on the location of the well, size of drilling crew, total depth of the well, etc.). The process of pulling tools out of the ground alongside the drilling rig is no longer necessary, because the new well can be drilled through the existing production tubing. Another advantage of TTRD is that the driller is able to control and rotate the pipe inside the completion tubing thereby reducing potential friction from sliding. This method has revolutionized oil and gas wells drilling worldwide.

7. Coiled Tubing Units (CTU)

This technology is not new because it has been used extensively many years ago in the North Slope for well bore re-completion and maintenance. CTU uses series of coiled-tubing units instead of drilling rigs for drilling and/or completion of wells Used previously for routine well services and maintenance, including completion and well logging by producers and drillers, it has found new use in the industry as money saving drilling tool technique to economically produce oil.

Coiled-tubing wells are drilled with truck-mounted coiled-tubing units instead of conventional rotary drills. The goal is to reduce the cost of the well by using a system that is less costly than a drilling rig. It gets the name Coiled-Tubing from, the drill bit, equipments, and motor assembly works connected to the end of a long string of flexible coiled metal tube that is lowered from the back of a “truck-mounted unit” at the surface.

Recent emergence and availability of new down-hole directional drilling tools or technological efficient drilling motors, and modern down-hole equipments make Coiled tubing a lot easier to use in drilling, completion and production processes successfully and efficiently at tremendous savings. While Coiled-tubing is commonly used as an alternative to certain types of wells such as the “sidetracks” drilled off the well bore of an existing older well, it can also stand alone as a formidable independent safe drilling rig.

8. Multilateral Wells Drilling and Completion (MWDC)

The Multilateral Wells Drilling and Completion technique involves drilling a new well off an existing old well with both wells sharing a vertical section that reaches the surface, and simultaneously completing and producing both wells at the same time but from different or same producing rock formations or reservoir. While MWDC may be similar to a “side-track,” well drilling method, it is different in that the older well is not cement and closed off; a new well that is drilled off from old existing well which can be co-mingled or independently completed for necessary production. Importantly it allows two or more wells to share the same “vertical bore hole section” that reaches to the surface with tremendous savings in well completion costs --especially cementing, drilling costs and other down hole facilities or infrastructures and materials costs, including time spent on drilling, completion and production.

9. Designer Wells

Designer wells are customized precision wells designed to unbelievable accuracy that incorporate various advances in drilling, completion and production technology to the extent of being very specific in its target of site, production formations, lithologic zones, oil and gas pools, field and/or reservoir; including specific production depth, thickness and magnitude of production possible. It uses technological advancement gained through the use of three-and four-dimensional seismic, which allows geologist, geophysicist and reservoir engineers to accurately identify, plot and ascertain the exact locations of possible oil and gas reservoir, its extent including but not limited to major and secondary fields, potential reserves, presence of faults, stratigraphic differences and traps, small isolated oil and gas traps all designed to within 100 to 200feet accuracy. With designer wells, drillers can now make previously impossible tight turns while drilling to about 55 degrees in 100 feet and, 100 degrees, about a quarter circle in 200 feet with potential for future capability to make from 270 degrees to 360 degrees or a full circle.

10. Freeze wall

Freeze wall creates a barrier freeze zone about one and half the size of a football field around specific drilling area underground to protect the water table so that no underground water and/or aquifer is contaminated. A system is set up to pump out the water from the drilling area of the freeze wall.

11. In-situ Conversion Process (ICP)

Pioneered by Shell and currently in experimental stage, ICP involves heating the ground around and below the drilling rig, especially areas within the confines of the oil shale formation for an extended period of time. When the shale formation is heated enough, the oil and gas within is release and recovered. This in-ground heating process has been able to successfully recover large amount of oil and natural gas from shallower less-concentrated oil shale formation layers. According to Shell, the research to date has fully demonstrated that the In-situ Conversion Process (ICP) works technically on a small scale, but commercial application and large scale production using this technique is currently underway.

12. Flexible Rotation Drilling (FRD)

Flexible Rotation Drilling otherwise known as “Degree in Degrees” is new drilling technology that allows drillers to make previously considered “extremely-difficult tight-turns” during the drilling process. It used to be impossible for drillers to make tight turns when drilling oil and gas wells through very tight consolidated solid rock formations. With this new drilling technique, drillers can now turn within the inside of wells by as much as 55 degree angle, within a distance of 100 feet, and could even turn up to 100 degrees, or nearly 1/4th of a circle as well as make angler turns greater than 90 degree in just 200 feet distance. Drillers reportedly have been able to make dramatic turns as much as 180 and 270 degrees successfully. Efforts are currently underway to improve on these incredible accomplishments and do a complete 360 degree rotation during drilling.

13. Riser-less Mud Recovery

The International Ocean Drilling Project, in a joint and collaborative effort with “AGR Drilling Services announced a new drilling and production technology called “Riser-less Mud Recovery” (RMR). This technology is designed purposively for extremely deep-water and ocean drilling. The “RMR” process is a simple “closed system,” where the mud and drilling fluids are kept independent and separate from the surrounding seawater. It makes it unnecessary to assemble and position risers that will surround the drill, in order to effectively draw the mud up to the surface.

All these new techniques have enabled oil and gas producers to explore, develop and produce new oil reserves Worldwide. These new techniques have lowered the prospecting, finding, drilling, completion and production costs of new crude oil and natural gas. It also has allowed more drilling to be done since drilling and well completion is less expensive than before. These savings have allowed oil producers to enjoy maximum savings that can be transfer to financially compensate other key oil and gas operations and management areas (such as transportation, labor and other materials costs) besides drilling and production costs.

Other New Techniques

RF/CF Technology

This electronic transmission based technology was developed by Raytheon and its partner CF Technologies specifically for recovery and processing of oil shale formation. It combines radio frequency (RF) technology from Raytheon with critical fluid (CF) technology from CF Technologies.

Wells are drilled into the shale formation strata using standard drilling equipments. However, an RF antennae, and/or transmitters, are lowered into the oil shale beds at the desired zone. The antennae transmit RF energy that uniformly heats the oil bearing shale formation rock. This eventually produces water volatilization process that creates micro-fracking of the formation, which in turn enhances the release of the crude oil forcing recovery.

Fishbone Method

A new approach pioneered by ConocoPhillips known as "fishbone," involves drilling multiple small well legs off an old well-bore similar to multi-lateral well. However, this fishbone approach is different because the lateral legs are open holes and are not cased in steel tubing. This technique relies on primary production without the use of enhanced or secondary recovery.

Steam- Flooding Process

Another new approach includes but is not limited to Steam-Flooding currently being tested with heavy oil development in many producing areas of Canada. It involves simultaneously drilling two or more wells and injecting hot steam into one or two of the wells to produce the primary well.

The hot steam is supposedly injected into the reservoir through the injection wells and it warms or loosen the crude oil around the producing well, allowing the crude oil to flow and be produced.

The drawback with this approach is that it requires a reservoir with thick rock formation layers, enough to not only support the two wells and steam-induced thaw "bulb" around the producing well, but be able to hold constant the necessary steam temperature and pressure required to thaw the crude oil enough for it to flow.

Hydrates Gas (HG)

A study conducted by BP, but funded by the U.S. Department of Energy, concluded that it is possible that economically viable commercial quantity natural gas can be produce from hydrates with recent new technology. Hydrates contain large volume of gas and are found near existing oil and gas fields in the North Slope of Alaska and places in Canada. This can be a new source of additional gas that will dramatically increase what is currently available now.

Moveable Drilling Rig

Doyon Drilling is reportedly using creatively designed drilling rigs that are efficiently mobile and are easily relocated from one well to another. This moveable drilling rig has deployed for use at several oil and gas drilling and production locations.

New Refining Technology

The current success achieved to date has prompted and instill more confidence of a brighter future for oil and gas producers, and the oil industry –especially the major refiners. Importantly, major advances are currently underway in the area of crude oil refinery, with the advent of bigger and better refineries, exhibiting increase processing capacity in separating, converting, and finishing the many compounds found in petroleum.

Oil Refinery

Crude oil selection continues to play significant role in the general operational decision of refineries. The most important criteria to determine which crude to acquire and refine include but are not limited to type of crude, reliability and source, discount delivery and product demand, plant operation flexibility and environmental concerns. As a result, new technologies are addressing problems of high-acid crudes (HACs), and heavy extra-heavy oils containing various amounts of bottom-of-the barrel (BOB) fractions.

Information Technology (IT)

New, innovative information technologies are helping companies to remotely and automatically monitor wells and oil/gas fields, and consequently take preventative measures to help avoid complex production problems and serious downtime.

In Summary

Due to advance in science and technology in the oil and gas industry, drilling and production process have improved, and producers are now able to drill faster, farther, better and deeper while they produce from tight formations, and extract oil and natural gas from places never previously imagined. With these new methods we can design our drilling rigs and procedures to drill four to six horizontal cased or none cased wellbores from a single drill pad, and produce from all of them through two or more formations simultaneously. We have been able to drill better, faster, safer and in shorter time that we ever could in the past. We have been able to penetrate through a much harder rock formations and other natural obstacles than we thought ever possible by rotating the rig, drilling horizontally, or at unbelievable drill angles. We have been able to produce more crude oil and natural gas from oil shale than we ever thought possible in the past.

Technology aided oil and gas data have helped improved reservoir analysis, and produced more oil and natural gas than before. This is not the end; new generations of oil and gas technology will still be needed to develop even more difficult and challenging oil and gas deposits especially those that were still considered to be, uneconomic to produce. With all these various advances in the oil and gas industry, the exploration drilling and production companies, engineering contractors, drillers and producers have been able to utilize technology to generate and produce better information for exploration, discoveries and exploitations of new and old fields.

Our basic resources have not changed in terms of values added to oil and gas operations, but the functional approach through which these resources are utilize may determine efficiency and effectiveness of operations.

Here at Black Crystal Oil and Gas we stand to take advantage of these various advances in technologies and use them to our benefit during our operations in the upstream, mid-stream and downstream sectors.

Black Crystal Oil  Gas

Gas

“Excellence is a habit and it is the soul of our business”

P. O. Box 794734 Dallas, TX 75379-4734. USA. Email: mail@blackcrystaloilandgas.com